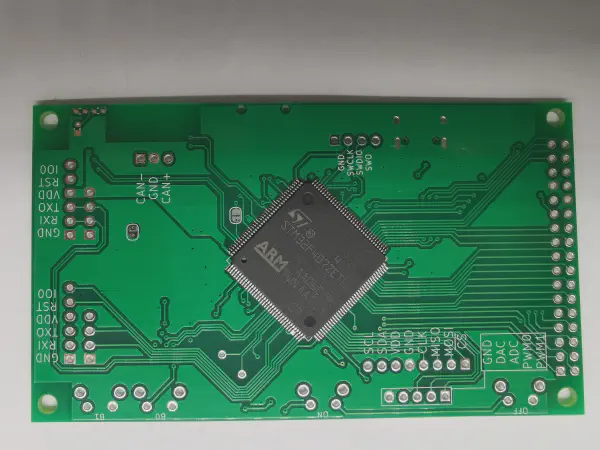

As mentioned in part four of the STM series, that development board was sponsored by PCBWay.

For this review, they agreed to allow for assembly of two of the boards which is excellent as I can compare their assembly service. Since the Elecrow review, I have used their assembly service a few times for projects and generally been very impressed with the quality and contact.

At a high level, the PCBWay ordering process was a lot more personal than I have worked with other unnamed vendors; which is fantastic if you are unsure in your designs and would like someone to review the design to make sure it’s actually manufacturable. Otherwise, everything is as you expect, the boards arrive on time, they all work and the assembly is done well.

You definitely get more than what you pay in terms of quality and service.

Ordering process + assembly time

Ordering at PCBWay is fairly straight forward; upload your gerbers and submit them through for approval. This is however where it deviates from some other companies when you create an account you are assigned a contact person. This appears in the corner of your profile and account and is the same person for every order. This means that you are always working with the same member of staff for all of your orders which is a nice touch.

Working with PCBWay feels more like older style companies where you can talk to a member of staff about any questions.

When you place the order components into your card their system provides an estimated time for the completion of the items. IN the case of this order, the estimated time for the PCB’s themselves was 24 hours or less. Their website has the fantastic progress tracker like JLC, and so I can confirm according to the tracker that the manufacturing took 26 hours from payment clearing until the PCB was ready to ship. 26 hours is very good for a timeframe in processing a PCB order. Especially considering that this order was placed during the peak order time after CNY.

For the assembly order, the total production time was estimated at 40-50 days total time, however, it was completed and shipped in 23 days. This was a nice surprise, and I estimate that the 40-day figure is most likely a worst-case timeframe for complex designs with complex orders.

For my design, I specified the Digikey part numbers and uploaded a bom and the .pos file from KiCad.

The whole ordering process was very quick and easy to submit.

Once all of the files were uploaded to PCBWay, around 24 hours or less the order was approved to be paid for. I’m assuming during this a member of staff looked at the files and ensured they were both valid and able to be produced on their equipment. For first time orders for PCB runs this can be a very comforting check, as forgetting files should get flagged and prevent a wasted order.

Outside of this, the entire ordering process was absolutely normal for all other fabrication locations.

Quality of PCB

Quality of the footprints

usbc

Looking at the USB-C footprint, all of the pads are etched correctly (no rounded corners). The solder mask is cleanly masked away from the footprint (nice rectangular cutout). The holes milled in the PCB are also in the correct locations, and no damage is visible.

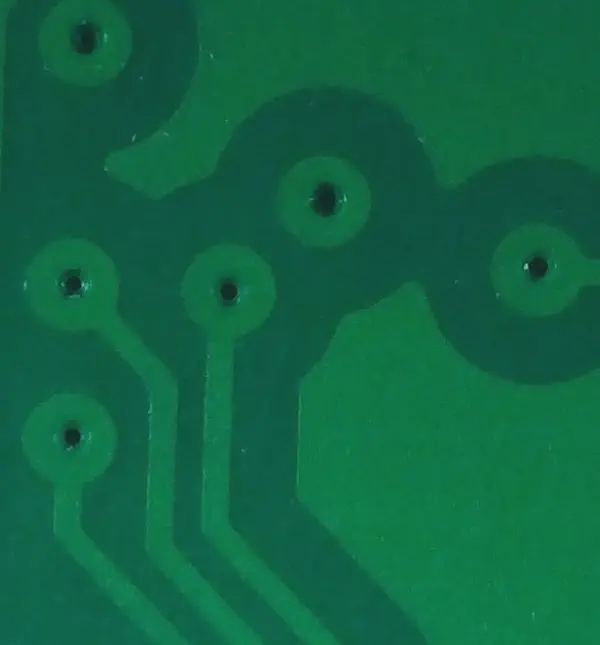

Quality of the vias

vias

While this design is not pushing any limits. It a very good indication of their quality control that all of the drill holes line up in the centre of the via pad (within reason).

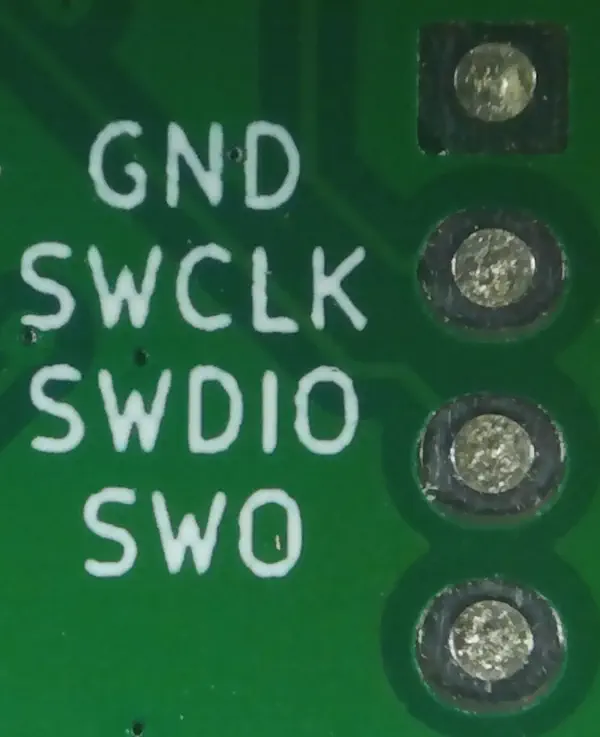

Silkscreen & resist quality

silkscreen

soldermask

Looking at the silkscreen print quality, you can see the slight unevenness in the printing that was used to apply this layer. However, it is massively better than the quality that dirtypcbs will usually turn around.

The second, random-looking scratch is created by dragging a sharp tool across the surface of the solder mask. Key features here are looking for the solder mask flaking off (which some JLC PCB’s have done). Soldermask quality

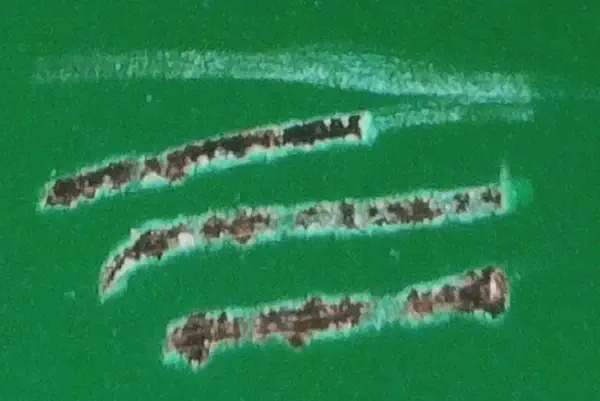

Quality of assembly

Sample of contact image

PCBway check image

Above is the image that was sent to me by PCBway. The first thing is that is a very clear photo so that there is no doubt about the orientation of the components. In this order, I only had the assemble the STM32F407 as the TQFP is certified not fun to solder. The soldering job here is absolutely excellent (much better than what I can do). The image is their original file, no editing on my side.

Soldering quality

shorts

Looking at the assembled reflow of the TQFP that I had fitted to these boards, the soldering quality is A+. After running full functionality tests on the assembled boards, every single joint was correct and required no corrections.

Overall wrap up

Overall the quality of PCBWay is very high, I have used them for some previous projects (a year or two back) and have always had orders arrive on time (typically faster than the estimate), and the quality is on point.

For assembly, I will most likely come back to PCBWay for small run assembly. I’m slowly moving from assembling all of my own projects to outsourcing the assembly to save time.

For open clarity, this sample run was a total of :

- $54 USD for assembly including the 2x STM32F407ZET6. ($23 worth of parts)

- USD 8 for each set of 10 boards, up to 10x10cm.

For the time saved of not having to solder 188 TQFP pins, this is a very good price. USD 30 is very cheap to save me the time of assembly.

So, I will definitely be bringing my assembly orders to PCBWay (also free DHL on large orders!). I will reccomend PCBWay as a very capable PCB fabrication group, and will be my go-to for future assembly work.